THine Value Achieving Completely Connectorless HDMI Wireless Transmission with Millimeter-Wave Communication and Wireless Power Supply

2024.12.05

- Article

- Solution

HDMI and DisplayPort are the most prevalent video interfaces, with which many individuals are familiar through manually connecting them to link a PC to a display. Typically, once established at home, these connections remain undisturbed.

However, some applications require repeatedly connecting and disconnecting these interfaces, such as testing display-equipped devices on a production line. Workers must plug the video interface connectors into each device, remove them after inspection, and connect to the next device, often multiple times a day. Such repetitive tasks not only demand labor but also increase the risk of connector damage.

Another example is automotive displays (optional equipment), where HDMI interfaces may also require repeated connections and disconnections. For instance, children often connect smartphones or handheld gaming devices via HDMI. If these connectors are exposed, accidental spills of water or juice may cause connection failures.

However, some applications require repeatedly connecting and disconnecting these interfaces, such as testing display-equipped devices on a production line. Workers must plug the video interface connectors into each device, remove them after inspection, and connect to the next device, often multiple times a day. Such repetitive tasks not only demand labor but also increase the risk of connector damage.

Another example is automotive displays (optional equipment), where HDMI interfaces may also require repeated connections and disconnections. For instance, children often connect smartphones or handheld gaming devices via HDMI. If these connectors are exposed, accidental spills of water or juice may cause connection failures.

Transmitting HDMI Signals via Millimeter Waves

To address these challenges, we developed the Contactless Display Adapter, which wirelessly transmits video interfaces between PCs and displays (Figure 1). This wireless transmission is achieved using 60 GHz millimeter-wave communication.

The developed device consists of a transmission unit (Tx unit) and a receiving unit (Rx unit) (Figure 2). The video interface supports HDMI, with HDMI as the input for the transmission unit and the output for the receiving unit.

The device is extremely simple to use. Each unit has a protrusion and corresponding slots; aligning the two protrusions by stacking the units completes the positioning of the transmission and receiving units, and wireless transmission of the video signal can begin (Figure 3). There is no need to plug in connectors physically.

Furthermore, the Contactless Display Adapter features Wireless Power Transfer (WPT) capability, enabling a supply of power to the receiving unit. As mentioned earlier, aligning the two protrusions initiates wireless power transfer first, followed by video interface wireless transmission. This eliminates the need to connect a power connector to the receiving unit.

Consequently, using the Contactless Display Adapter provides two major benefits. First, it improves throughput by eliminating the need to plug and unplug connectors repeatedly. Although the time spent on making each connection is short, frequent repetition can accumulate significant time losses. Eliminating this time can greatly enhance operational efficiency, such as in display device testing mentioned earlier.

Secondly, it prevents wear and tear on connectors, as wireless transmission inherently eliminates the need for physical connectors, thereby avoiding physical wear on the connector.

Additionally, the device offers the advantage of electrical isolation between the transmission and receiving units. Depending on the application of the video interface, it may be necessary to electrically isolate the transmitting and receiving sides of the video signal to ensure a high level of safety. The device we have developed will make it possible to meet this demand.

Figure 1 Contactless Display Adapter for wireless transmission of video interfaces

The developed device consists of a transmission unit (Tx unit) and a receiving unit (Rx unit) (Figure 2). The video interface supports HDMI, with HDMI as the input for the transmission unit and the output for the receiving unit.

Figure 2 Transmission unit and receiving unit of the Contactless Display Adapter

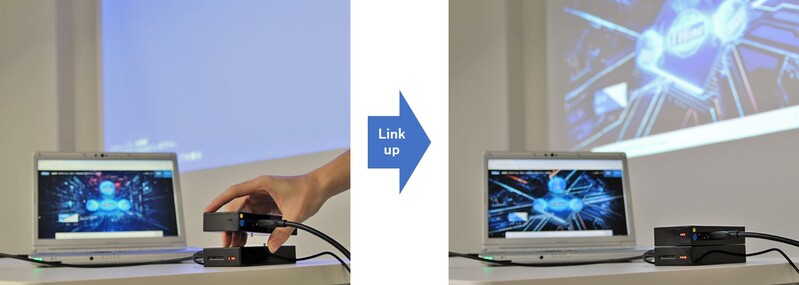

The device is extremely simple to use. Each unit has a protrusion and corresponding slots; aligning the two protrusions by stacking the units completes the positioning of the transmission and receiving units, and wireless transmission of the video signal can begin (Figure 3). There is no need to plug in connectors physically.

Figure 3 Easy positioning process

Furthermore, the Contactless Display Adapter features Wireless Power Transfer (WPT) capability, enabling a supply of power to the receiving unit. As mentioned earlier, aligning the two protrusions initiates wireless power transfer first, followed by video interface wireless transmission. This eliminates the need to connect a power connector to the receiving unit.

Consequently, using the Contactless Display Adapter provides two major benefits. First, it improves throughput by eliminating the need to plug and unplug connectors repeatedly. Although the time spent on making each connection is short, frequent repetition can accumulate significant time losses. Eliminating this time can greatly enhance operational efficiency, such as in display device testing mentioned earlier.

Secondly, it prevents wear and tear on connectors, as wireless transmission inherently eliminates the need for physical connectors, thereby avoiding physical wear on the connector.

Additionally, the device offers the advantage of electrical isolation between the transmission and receiving units. Depending on the application of the video interface, it may be necessary to electrically isolate the transmitting and receiving sides of the video signal to ensure a high level of safety. The device we have developed will make it possible to meet this demand.

Adopting an Interface Optimized for Wireless Transmission

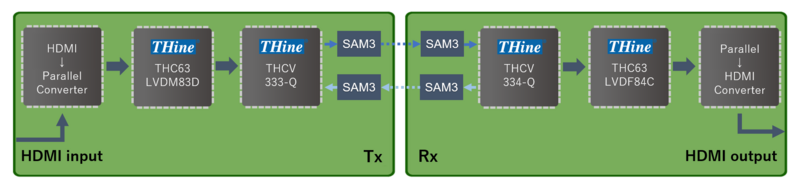

The Contactless Display Adapter adopts our proprietary video interface standard V-by-One HS II and utilizes the SerDes chipset THCV333-Q/THCV334-Q. Why did we choose a chipset that supports V-by-One HS II? Before explaining why, let us first explain the flow of video signals throughout the entire wireless transmission system (Figure 4).

In the transmission unit, the video signal (HDMI signal) output from a PC is first converted into a parallel signal by a converter, then into an LVDS signal by the THC63LVDM83D. Next, the serializer IC THCV333-Q converts it into a V-by-One HS II signal, which is then wirelessly transmitted to the receiving unit via the millimeter-wave communication module SAM3.

Conversely, in the receiving unit, the process is reversed to convert the signal back into a video signal (HDMI signal) for input to the display. Specifically, the SAM3 module receives the millimeter-wave signal and extracts the V-by-One HS II signal. The deserializer IC THCV334-Q then converts it into an LVDS signal, which is further converted into a parallel signal by the THC63LVDF84C and finally back into an HDMI signal by a converter.

The greatest advantage of V-by-One HS II lies in its transmission method. Let us get into the details. V-by-One HS II provides a forward channel (from the transmission circuit to the receiving circuit) and a back channel (from the receiving circuit to the transmission circuit). The forward channel transmits video signals along with control signals embedded as packets, while the back channel transmits only control signals. The THCV333-Q and THCV334-Q allow either multiplexing these two signals for bidirectional transmission with fewer wires or separating them for unidirectional transmission with separate wires, selectable via register settings. This makes them particularly suitable for wireless (or optical) transmission. In fact, the Contactless Display Adapter utilizes four SAM3 millimeter-wave communication modules, with two modules each for the forward and back channels.

Previously, our technology used a main link based on V-by-One HS for video signals and a separate sub-link for control signals, forming two transmission channels. While the main link was unidirectional, the sub-link was bidirectional, making it unsuitable for wireless (or optical) transmission. This time, adopting V-by-One HS II and the THCV333-Q/THCV334-Q has made wireless HDMI transmission comparatively easier to achieve.

Figure 4 Video signal flow between the transmission and receiving units

In the transmission unit, the video signal (HDMI signal) output from a PC is first converted into a parallel signal by a converter, then into an LVDS signal by the THC63LVDM83D. Next, the serializer IC THCV333-Q converts it into a V-by-One HS II signal, which is then wirelessly transmitted to the receiving unit via the millimeter-wave communication module SAM3.

Conversely, in the receiving unit, the process is reversed to convert the signal back into a video signal (HDMI signal) for input to the display. Specifically, the SAM3 module receives the millimeter-wave signal and extracts the V-by-One HS II signal. The deserializer IC THCV334-Q then converts it into an LVDS signal, which is further converted into a parallel signal by the THC63LVDF84C and finally back into an HDMI signal by a converter.

The greatest advantage of V-by-One HS II lies in its transmission method. Let us get into the details. V-by-One HS II provides a forward channel (from the transmission circuit to the receiving circuit) and a back channel (from the receiving circuit to the transmission circuit). The forward channel transmits video signals along with control signals embedded as packets, while the back channel transmits only control signals. The THCV333-Q and THCV334-Q allow either multiplexing these two signals for bidirectional transmission with fewer wires or separating them for unidirectional transmission with separate wires, selectable via register settings. This makes them particularly suitable for wireless (or optical) transmission. In fact, the Contactless Display Adapter utilizes four SAM3 millimeter-wave communication modules, with two modules each for the forward and back channels.

Previously, our technology used a main link based on V-by-One HS for video signals and a separate sub-link for control signals, forming two transmission channels. While the main link was unidirectional, the sub-link was bidirectional, making it unsuitable for wireless (or optical) transmission. This time, adopting V-by-One HS II and the THCV333-Q/THCV334-Q has made wireless HDMI transmission comparatively easier to achieve.

Effective Utilization of the Back Channel

The SAM3 millimeter-wave communication module, a product of SENSORVIEW in South Korea, incorporates the ST60A2 millimeter-wave transceiver IC from STMicroelectronics in conjunction with SENSORVIEW's proprietary patch antenna.

Wireless power transfer uses the WPT module by B&PLUS, which is capable of supplying up to 10 W of power. The back channel is used for transmitting signals that confirm the establishment of power transfer between the wireless power transmission coil and the receiving coil. If there is no corresponding receiving coil, continued power transmission from the transmitting coil can result in significant power loss. To prevent this, if no signal is returned from the receiving unit via the back channel, wireless power transfer is stopped to minimize power loss and overheating.

End

Wireless power transfer uses the WPT module by B&PLUS, which is capable of supplying up to 10 W of power. The back channel is used for transmitting signals that confirm the establishment of power transfer between the wireless power transmission coil and the receiving coil. If there is no corresponding receiving coil, continued power transmission from the transmitting coil can result in significant power loss. To prevent this, if no signal is returned from the receiving unit via the back channel, wireless power transfer is stopped to minimize power loss and overheating.

End