THine Value In-depth Comparison of Camera Modules for Industrial Equipment: Pros and Cons of UVC Cameras, IP Cameras, Wi-Fi Cameras, and MIPI Cameras

2023.09.12

- Article

- Column

Embedded camera modules for industrial equipment and other applications have evolved remarkably. In addition to resolution and frame rate improvements, external dimensions are shrinking, costs are being reduced, and usability is improving rapidly. For this reason, it is becoming commonplace to see these devices installed in robots, drones, medical equipment, POS terminals, automated teller machines (ATMs), and vending machines, not to mention inspection/measurement equipment and surveillance cameras for factory production lines (Fig. 1).

Incorporating camera modules into such industrial equipment allows for adding new functions that have not been possible before. For example, equipping vending machines with a camera module can allow for obtaining the gender and age data of customers using images captured by the module, which can then be used to optimize the lineup of beverages to be sold. In other words, these devices can be used to acquire marketing data. Undoubtedly, more industrial equipment will be equipped with camera modules in the future.

Fig. 1 Examples of industrial equipment with camera functions

Incorporating camera modules into such industrial equipment allows for adding new functions that have not been possible before. For example, equipping vending machines with a camera module can allow for obtaining the gender and age data of customers using images captured by the module, which can then be used to optimize the lineup of beverages to be sold. In other words, these devices can be used to acquire marketing data. Undoubtedly, more industrial equipment will be equipped with camera modules in the future.

Four Cameras to Choose From

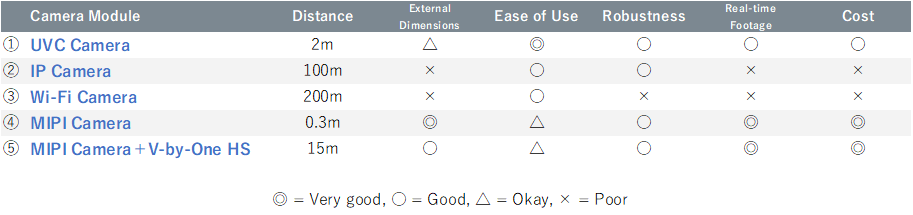

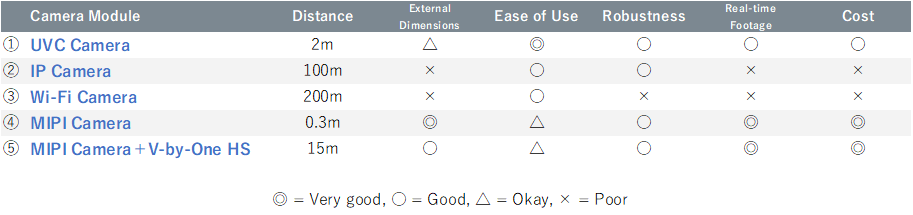

However, integrating a camera module into industrial equipment requires overcoming several obstacles, although they are by no means complicated. The first challenge engineers encounter at industrial equipment manufacturers is camera module selection. At present, there are four major camera module options. Specifically, these four types of camera modules are USB Video Class (UVC) cameras, Internet Protocol (IP) cameras, Wi-Fi cameras, and Mobile Industry Processor Interface (MIPI) cameras. These four camera modules are briefly described below.

However, the disadvantages related to connection distance can be eliminated to some extent if appropriate measures are taken. Specifically, MIPI cameras can be combined with the V-by-One HS high-speed serial interface from THine Electronics ((5) MIPI Camera + V-by-One HS in Table 1). This combination would extend the connection distance to about 15 m (Fig. 2). Moreover, there are few disadvantages that arise from this combination. The only disadvantage is a slight increase in component and development costs. The advantages of small external dimensions and the robustness of the connection remain unchanged.

Table 1 Camera module options for industrial equipment

① UVC Cameras

UVC camera modules are connected via a USB cable. Most webcams connected to PCs for online conferencing and video streaming use these UVC camera modules. The advantage of these modules lies in their ease of use. This is because the module is compliant with the USB Video Class (UVC) standard, meaning the driver software is preinstalled in the computer's OS. The user simply connects the UVC camera to their computer, displaying the image on their monitor. Therefore, there is no need to develop driver software when integrating into industrial equipment. On the other hand, there are some disadvantages. Since UVC cameras are end products in themselves, their external dimensions are large, and their cost is high for camera modules to be incorporated into industrial equipment.② IP Cameras

IP cameras are modules connected via Ethernet cables. The camera has an IP address and can be used simply by connecting the module to the Internet. These devices are sometimes also called network cameras. The main applications for these devices are for surveillance, but they can also be used for integration into industrial equipment. Their advantage is the same ease of use as with UVC cameras. There is no need to develop driver software when integrating a module into industrial equipment. Another advantage is that the connection distance is as long as 100 m. These modules can be used to monitor remote locations. The disadvantages are large external dimensions and high cost, similar to UVC cameras. A further disadvantage is that video signals are compressed for transmission, making real-time transmission impossible, resulting in a video delay of several frames.③ Wi-Fi Cameras

Wi-Fi cameras are positioned as a wireless LAN (Wi-Fi) version of the above IP camera. Thus, this allows wireless communication between the camera module and the monitor displaying the images. This wireless communication is the biggest advantage. Moreover, the connection distance can be long, up to approximately 200 m, making it highly user-friendly. The disadvantage of these modules is that, as with IP cameras, real-time transmission is not possible. Furthermore, there is a risk of disconnection depending on the surrounding environment, and the robustness of the connection is relatively low, raising security concerns. In addition, the large external dimensions and high cost for a camera module to be incorporated into industrial equipment may be cited as disadvantages.④ MIPI Cameras

MIPI cameras are modules that use MIPI CSI-2, a transmission standard that connects the camera to the SoC inside mobile devices, such as smartphones, as its video output interface. The advantage of using these modules is that the external dimensions are small, and the cost is low because they were originally intended for mobile devices. Further advantages include the possibility of real-time transmission and the robustness of the connection. On the other hand, there are two disadvantages. One is that the connection distance is short, being 30 cm at most. This makes it difficult to apply to industrial equipment where the distance between the camera module and the video processor is far. The other disadvantage is the need to develop driver software and write register code when integrating into industrial equipment. Unlike UVC and IP cameras, MIPI cameras cannot display video footage by simply connecting the camera.However, the disadvantages related to connection distance can be eliminated to some extent if appropriate measures are taken. Specifically, MIPI cameras can be combined with the V-by-One HS high-speed serial interface from THine Electronics ((5) MIPI Camera + V-by-One HS in Table 1). This combination would extend the connection distance to about 15 m (Fig. 2). Moreover, there are few disadvantages that arise from this combination. The only disadvantage is a slight increase in component and development costs. The advantages of small external dimensions and the robustness of the connection remain unchanged.

Fig. 2 Combining a MIPI camera and V-by-One HS

The disadvantage of increased development costs when combining MIPI cameras with V-by-One HS can be largely eliminated with the MIPI Camera SerDes Starter Kit offered by THine Electronics. This starter kit includes a complete set of software required to send and receive MIPI CSI-2 signals and also provides a graphic user interface (GUI) tool that automatically generates register codes.The Best Camera Depends on the Application

Which camera module is best suited for the industrial equipment you are developing? There is no one-size-fits-all camera module that works for all industrial equipment applications. In other words, the optimal camera module depends on the industrial equipment. Therefore, it is necessary to select the optimal camera module after carefully examining the characteristics of the industrial equipment in which it will be incorporated. Let us consider which camera module is suited for each of the five possible usage scenarios below.

However, the distance to the image processor may be far when retrofitting industrial equipment. The maximum transmission distance of a MIPI camera module is 30 cm, so it is assumed that the distance is insufficient. This problem can be solved by combining the module with V-by-One HS, a high-speed serial interface. The interface can extend the transmission distance to approximately 15 m.

Sometimes, POS terminals and other business equipment allow a separately sold (optional) camera to be connected to the terminal. The purpose is to allow users to respond to a need to read QR codes after the main device has already been purchased. In this case, the end user purchases the camera and connects it to the terminal or similar device. Therefore, the most important thing is to have the ability to make a connection extremely easily, making UVC cameras the optimal solution.

End

●UVC Cameras for Verifying Ideas

Attaching a camera module to industrial equipment and using AI to recognize the images from the module is sure to expand functionality. There will be times when this kind of idea suddenly pops into your mind. To validate your idea, speed is of utmost importance in the proof-of-concept stage (PoC). In this case, a highly user-friendly UVC camera would be the best choice. With UVC cameras, the video signal can be acquired immediately using a simple connection via USB cable, allowing the user to quickly work on validating their idea.●MIPI Cameras for Industrial Equipment with Limited Mounting Space

When retrofitting a camera module to an already completed industrial device, there are often cases where there is already little space available for mounting. For example, let us look into retrofitting vending machines and inspection/measurement equipment for production lines. In these cases, it is difficult to adopt UVC or IP cameras with large external dimensions. So, the MIPI camera, originally developed for mobile devices, is the best solution. With MIPI camera modules, products with external dimensions of approximately 20 mm x 20 mm are available, allowing mounting even in limited space.However, the distance to the image processor may be far when retrofitting industrial equipment. The maximum transmission distance of a MIPI camera module is 30 cm, so it is assumed that the distance is insufficient. This problem can be solved by combining the module with V-by-One HS, a high-speed serial interface. The interface can extend the transmission distance to approximately 15 m.

●IP Camera if Video Signal Transmission Distance Exceeds 100 m

For some industrial devices, the location where the video is taken and where the video signal is processed can be very far. Examples include broadcasting equipment installed in concert halls and other venues and underwater camera systems that transmit images taken underwater to ships. The required transmission distance in these scenarios can exceed 100 m. Therefore, supporting a UVC camera or a MIPI camera + V-by-One HS interface is difficult. To this end, an IP camera would be the best solution.●Wi-Fi Camera or MIPI Camera + V-by-One HS when Cable Routing is Difficult

When camera modules are integrated into industrial equipment, cable routing can cause some trouble. For example, let us look into a case of installing cables inside industrial equipment with complex mechanical structures. Installation becomes more difficult with thicker cables. In this case, using the thinnest possible cable makes routing work easier. The optimal solution, then, is a MIPI camera + V-by-One HS. Because V-by-One HS is a serial interface, video signals can be sent using fewer cables. In addition, a Wi-Fi camera can be used if the external dimensions and cost are acceptable. Using a Wi-Fi camera would make cables unnecessary in the first place, freeing the user from cable routing work.●UVC Cameras for Allowing the Connection of Separately Sold (Optional) Cameras

CamerasSometimes, POS terminals and other business equipment allow a separately sold (optional) camera to be connected to the terminal. The purpose is to allow users to respond to a need to read QR codes after the main device has already been purchased. In this case, the end user purchases the camera and connects it to the terminal or similar device. Therefore, the most important thing is to have the ability to make a connection extremely easily, making UVC cameras the optimal solution.

End